Flamastic® Customized Solutions

For challenging fields of application and safety in all areas

Our goal is to develop individual, application-specific solutions together with you. To this end, we have revived our traditional brand Flamastic® and dedicated a separate segment in our Fire Protectors portfolio to the field of “Customized Solutions”.

We offer you:

- Know-how in all known passive fire protection technologies

- Agile R&D team with decades of formulation experience

- Excellent R&D lab equipment incl. fire test facilities

- Expertise on applicable fire protection regulations

- Integration of our fire protection technologies in plastic parts of all kinds

- Professional project management

With over 60 years of experience in passive structural fire protection, we transfer our know-how to adjacent fields in this area and increasingly also to other industries. In addition to the construction-related industries, these include above all applications relating to the mobility and infrastructure of the future as well as areas of application relating to electronic devices in the end-user segment.

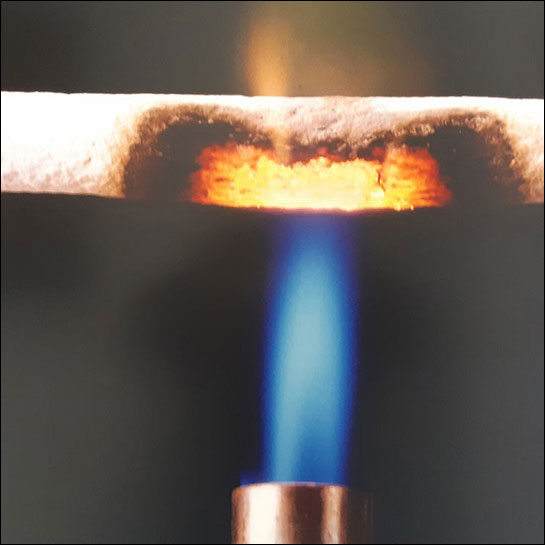

Intumescence*

Silicate based solutions:

Formation of insulation layers with expanded pressure and rigid foam

Graphite based solutions:

Formation of insulation layers with expanded pressure and soft elastic foam

Fire Protection technology in three variants

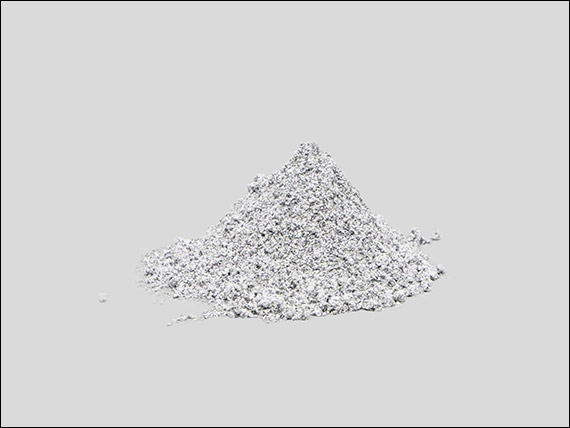

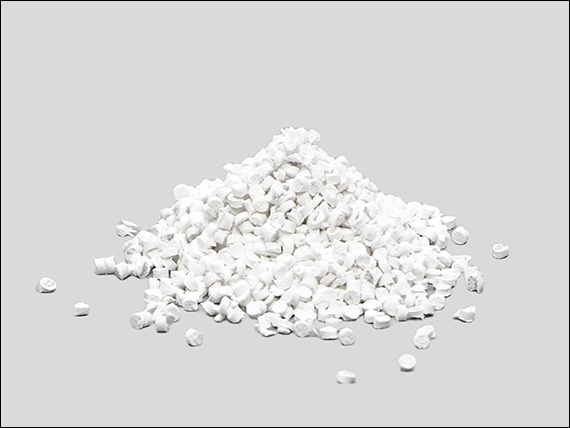

As part of our Flamastic® Customized Solutions portfolio, we offer you a wide range of application options – tailored to your needs. In addition, all Flamastic® fire protection products – whether dry blends, pastes, compounds or films – are available on a graphite or phosphate basis. If you have any further questions about the properties or application areas of the products, please feel free to contact us at any time.

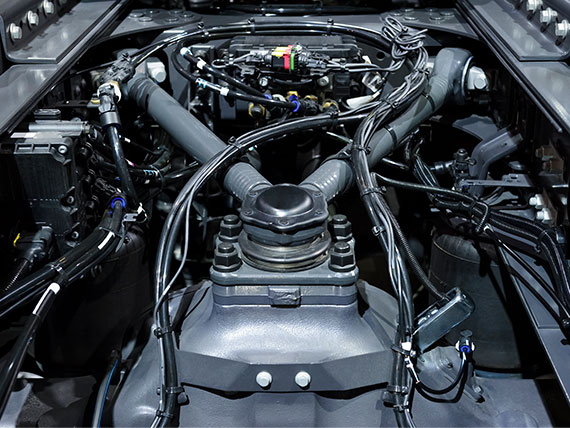

Solutions for electromobility

The increasing number of battery applications in mobility requires new solutions to counter the associated fire hazard. In particular, the thermal runaway of rechargeable battery systems must be shielded so that passengers have enough time to evacuate in the event of a fire.

Our solutions include coating or cladding of the vehicle structure, polymer films for the vehicle underbody to coatings for battery housings.

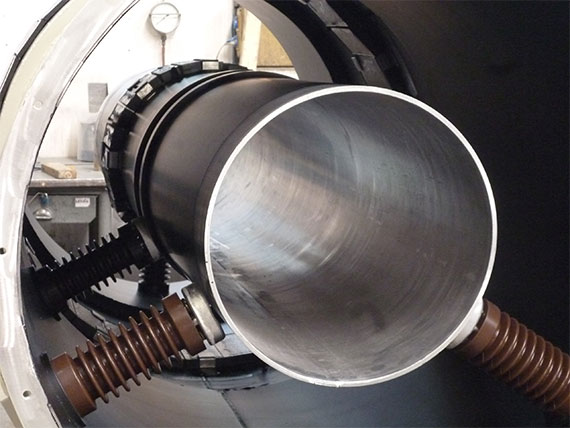

In order to find the right fire protection solution with our customers, we simulate the toughest fire loads in our own laboratories and test facilities. In the following example you can convince yourself of the high effectiveness of our fire protection solutions for batteries in the field of electromobility.

Your contact for advice & sales

André Klüger-von Loga

Business Manager Fire Protection Customized Solutions

Mobile: +49 152 54914350

E-Mail: andre.klueger-von-loga@wolman.de