Exterdens®

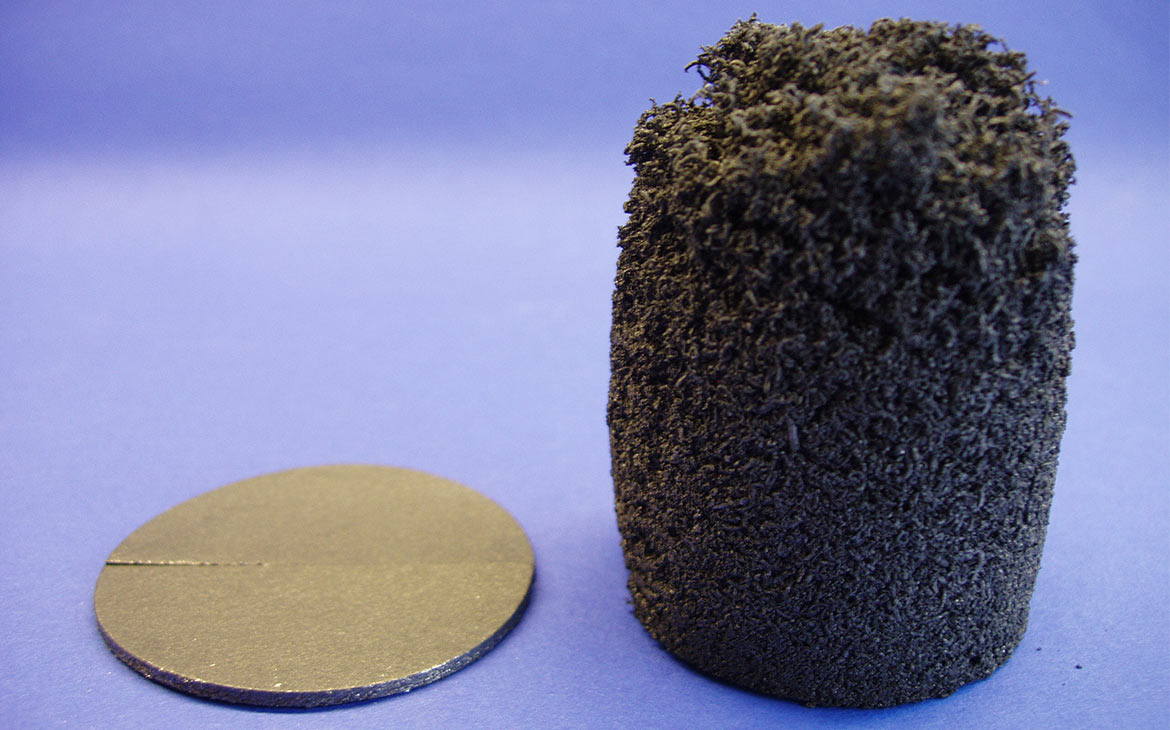

Foamed-up Exterdens® FB sheet: At a temperature of approx. 200°C, Exterdens® FB begins to expand to many times its original volume

Exterdens® foams with an inflation pressure of up to 10 bar at 150°C or 200°C and forms a microporous heat-insulating foam in the event of fire.

With the aid of graphite technology and the resulting inflation pressure, Exterdens® can also be used in a concealed manner, for example under veneer, and also in areas exposed to moisture. In the event of fire, the foam expands three-dimensionally and achieves foaming factors of up to 25 of its original volume, thus insulating and sealing joints and cavities against the flashover of fire and smoke.

- Effective extension of the fire resistance of building components

- Can be used in areas exposed to moisture

- Low response temperature from as low as 150°C

- Excellent protection due to the heat-insulating properties of the compact foam

- The three-dimensional foaming and the high foam factor enable the filling of large joints and cavities

- Due to the low panel thickness, expensive (door) materials or complex (door) constructions are not required

Exterdens® application range

Exterdens® is designed for use in exterior areas and in areas with increased exposure to moisture.

Exterdens® is used almost in all outdoor areas where passive fire protection is required. Exterdens® is used, among other things, in:

- Fire doors and gates

- Windows/ glazing

- Partition walls, ceilings and floors

- Safety cabinets and safes

- Ventilation systems

- Elevator systems

- Pipe and cable penetration seals

- Installation shafts and cable ducts

- Curtain walls

- Wooden constructions

- and much more

Exterdens® properties

Proven protection through graphite technology

- High foaming factor of up to 25 of its original volume

- High inflating pressure of up to 10 bar

- Fine-pored foam structure

- Reaction starts at 150°C

- Flexible material structure

Exterdens® product range

Exterdens® is available in rolls, some with self-adhesive finish. Exterdens® strips primarily protect component edges in areas exposed to moisture.