Palusol® SW

Selection of Palusol® SW panels as fire protection cores for wooden doors

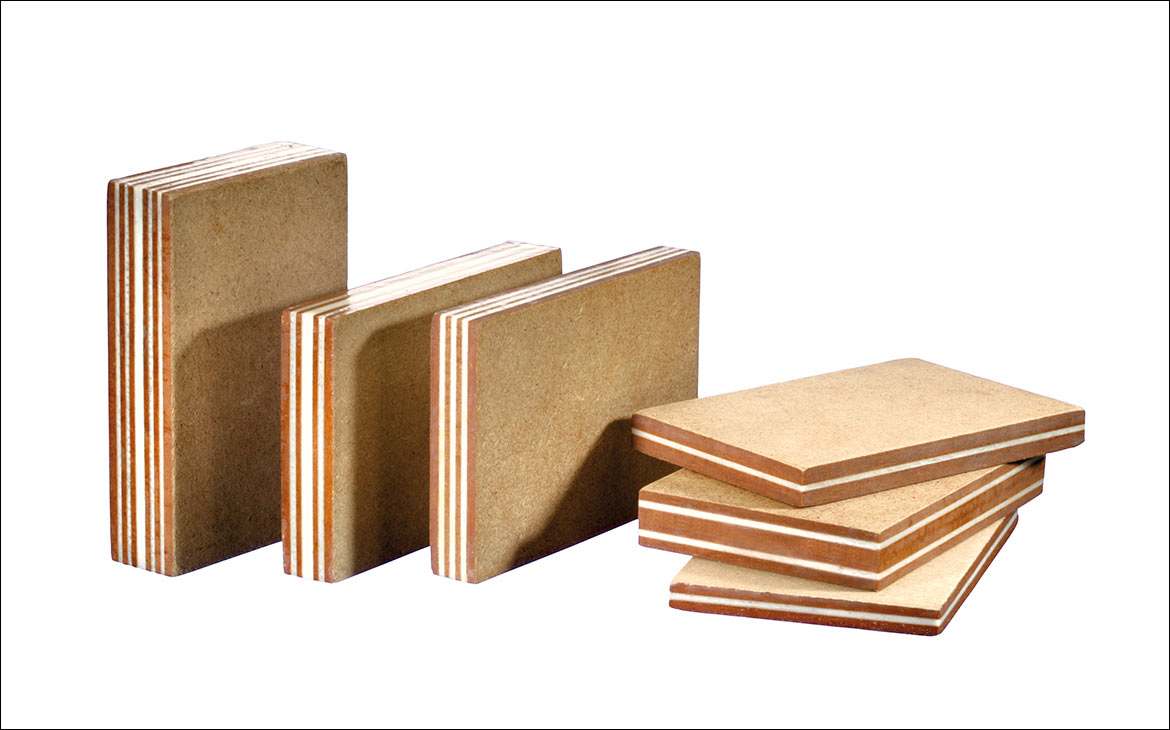

Palusol® SW the innovative pre-configured sandwich product.

Palusol® SW is a preconfigured sandwich product made of Palusol® fire protection sheets and high-density fiberboard (HDF). The different combinations and sequences of the individual layers form a torsionally stiff, fire-retardant board that has been specially developed for the manufacturing of wooden fire doors and for use in fire protection walls. In component tests, fire resistances of up to 90 minutes have been achieved.

- High fire-resistance combined with smoke and sound protection

- Thin-walled, torsionally stiff door cores allow low construction depths and therefore offer maximum individual design freedom for the door manufacturer

- Savings in cost- and labor-intensive process steps thanks to preconfigured fire door cores

- Cutting to size with tools commonly used in wood processing

- Since the outer layers of SW products consist of HDF boards, they can be glued with standard wood glues (white glues).

- The wood fiber boards used for sandwich production are from sustainable forestry and are marked and certified with the FSC® logo (License Code FSC-C006099)

- Free access to material and component certifications according to:

- ASTM (American Society for Testing and Materials)

- NFPA (National Fire Protection Association)

- CAN/ULC (Standards Council of Canada)

- BS (British Standards)

- Intertek Testing Services

- Quality Auditing Institute

- Guardian

Application Palusol® SW

Palusol® SW boards are mainly used as wooden fire door core, fire dampers and partition walls used for fire protection.

In the event of fire, the core of a fire door must ensure high fire resistance and at the same time provide high stability and torsional rigidity of the door. Strong thermally induced stresses occur as a result of deformations due to the temperature differences of up to 1000°C. Palusol® SW boards are designed to withstand mechanical stress, while at the same time providing freedom for different door designs. The wood door industry appreciates the wide range of fire door tests, which have been conducted by us over a development period of more than 15 years based on American ASTM/UL standards and according to British Standard (BS). The extensive range of component certifications allows designers to create virtually any type of fire door needed in a building with Palusol® SW boards.

Palusol® SW properties

Innovative protection through silicate technology combined with fiberboard made from naturally grown wood

- Fire-retardant

- Thin-walled door cores provide safe fire resistance from 20 to 90 min in combination with smoke and sound protection

- Certification and testing of products and components ensures high-quality standards and enables access to free licenses

- Low component thickness, i.e. low design and manufacturing costs and great freedom for aesthetic design

- Long-term proven

- Use of natural and almost unlimited raw materials

- Fire tests on twelve-year-old fire doors showed that there is no impairment of the fire protection functionality of the doors

- Maintenance of high-quality standards through regular in-house and external monitoring

- Innovative

- Customized solutions possible through freedom of door design

- Meets the stringent formaldehyde emission requirements of CARB Phase 2

- Continuous portfolio expansion of tested and certified fire doors

Palusol® SW product range

Palusol® SW sandwich boards have been specially developed to produce fire doors and for use in fire protection walls. The different combination of HDF panels and Palusol® allows fire resistances between 20 and 90 minutes to be achieved.

![[Translate to English:] [Translate to English:]](https://www.fire-protectors.com/fileadmin/user_upload/feuerschutz/produkte/header_palusol.webp)